Cummins

Cummins introduces a revolutionary clean air solution for all our Diesel Genset Customers. The Retrofit Emission Control Device (RECD) is designed based on filter-less technology by utilizing Electrostatic Precipitation fundamentals. It is highly efficient in improving air quality and can capture Particulate Matter Carbon from polluting the air with more than 70% efficiency. These RECDs custom designed for Cummins Gensets are compliant with the National Green Tribunal order O.A 681/2018. So get your RECD today and join Cummins in making a positive impact on the environment!

No Manual Testing

No Choking

Low Maintenance

No Filter Replacement

No Water Usage

No Chemical

No Solvent

Salient features

- Energy efficient as requires no active regeneration. No dependency on exhaust temperature.

- Robustness to wide variety and conditions of in-use DG sets. Remote installation possible

- Unmatched and minimal flow restriction compared to conventional filter based technologies.

- No additional fuel consumption penalty.

- On board diagnostics and telematics solution (IoT) with cloud based push notifications for users

- Separated particulate matter can be collected and used as a high value raw material in paint, dye and plastics industry hence no disposal requirements or secondary pollution

- Simple, efficient and robust design that gives consistent performance and long operational life.

- All weather proof and low maintenance designs

Technological Advantages

| Technology | PM Capture Efficiency | Initial Cost | Operational Cost | Prominent Failure Mode | Impact on Engine | Ease of maintenance | Robustness to exhaust challenges |

|---|---|---|---|---|---|---|---|

| Diesel Oxidation Catalyst (DOC) | 20-40% | Low | Negligible | Face plugging | Negligible | Not serviceable | No |

| DOC + Partial Flow Filters or Partial Oxidation Catalyst (PFF/POC) | 60-75% | Moderate to high | Moderate (fuel penalty due to back pressure) | Soot load & thermal event | Variable back pressure | Not serviceable | No |

| DOC + Diesel Particulate Filter (DPF) | >90% | High | High(fuel penalty due to back pressure) | Soot load & thermal event | Variable back pressure | Ash cleaning soot removal | No |

| Water/ Solvent Based Exhaust Scrubbers Solution | NA | High | Moderate to high (wash fluid and chemical replenishment) | Fouling and engine hydro-lock | Back pressure due to HE | Complex and frequent service | Probably Yes |

| Electrostatic Precipitator Technology | 80%-90% | Moderate | Negligible | None | Negligible & control parameter | Easy service | Yes |

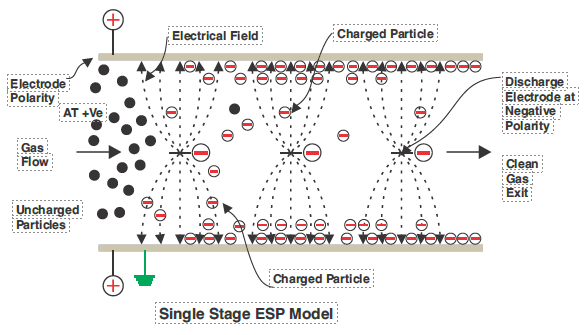

Working Principle

- The RECD is installed after the DG exhaust (muffler/silencer). No modification to the exhaust is required.

- Flue gas enters the RECD and is confronted with Corona discharge.

- Due to the contact with high voltage, the surface charge of the PM is nullified and PM gets attracted to electrodes of opposite charge

- The PM gets agglomerated and the size of the PM increases beyond PM10 (10 microns).

- This agglomerated PM is collected in powder form and is available for environmentally safe disposal/reuse.

| CUMMINS PART NUMBER | AX1016671 | AX1016672 | AX1016673 | AX1016674 | AX1016675 |

|---|---|---|---|---|---|

| APPLICABLE TO DG RATING (KVa) | 1010 | 1250 | 1500 | 1750 | 2000 |

| ENVELOPE - L x W x H (mm) | 2895 x 2100 x 2871 | 2895 x 2100 x 3219 | 2895 x 2970 x

2871 |

2895 x 2970 x 3219 | 2895 x 3840 x 2871 |

| APPROXIMATE GROSS WEIGHT (kg) | 2600 | 2900 | 3700 | 4000 | 4850 |

| OPERATIONAL POWER CONSUMPTION (kWe) | 1.5 | 2 | 2 | 2 | 3 |

| ENVIRONMENTAL PROTECTION | CANOPY | CANOPY | CANOPY | CANOPY | CANOPY |

| DESIGN BACK PRESSURE @ RATED (kPa) | <4 kPa | <4 kPa | <4 kPa | <4 kPa | <4 kPa |

| SOOT COLLECTION FREQUENCY* | 500 Hrs/Yearly | 500 Hrs/Yearly | 500 Hrs/Yearly | 500 Hrs/Yearly | 500 Hrs/Yearly |

| IoT CAPABILITY | Yes | Yes | Yes | Yes | Yes |

$ Excludes pipe projections and anchor brackets

* Operation dependent parameter

The product can be subject to any future changes in above specifications as continuous improvement efforts and compliances

Note: While RECDs are compliant to NGT order O.A 681/2018, the RECDs for DGs greater 800 KW are not certified by any CPCB

approved labs since the S&P for RECDs catering to DGs greater than 800 KW is not notified by CPCB